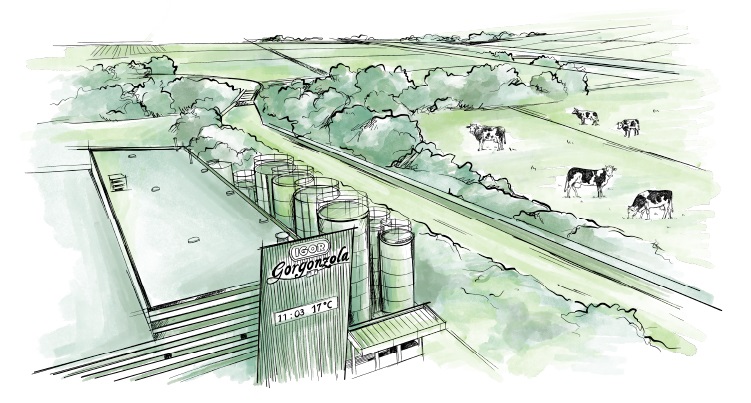

For four generations now, with unwavering passion and dedication, we have been producing Gorgonzola PDO, bringing it to tables all over the world.

The original recipe has remained untouched in the almost 90 years in business, fully respecting tradition and the environment.

Constantly committed to reaching the highest quality standard, from carefully selecting raw materials to meticulously monitoring every stage of the production process.

We have always believed in innovation, allowing us to improve our production processes to create a safe top-quality product that fully respects tradition.

We are a family business rooted in the local area for almost 90 years and made up of people who are an integral part of our success. Which is why we have always endeavoured to support the local community, through various sports, educational, cultural and social initiatives.

Our contribution is embodied in our ESG-related initiatives, actions, policies and goals detailed throughout the sustainability report.

IGOR’s gorgonzola is produced exclusively with milk from farms certified Animal Welfare, in compliance with the standards set by ClassyFarm.

Thanks to the use of resealable films and the elimination of plastic lids, IGOR has reduced plastic use in its packaging by 30%. Furthermore, from 2020 to the present, IGOR has removed 32 million plastic lids from its packaging.

In order to concretely reduce the polluting impact of the energy system and preserve the environmental resources of the planet, IGOR purchases electricity for its headquarter solely from certified 100% renewable sources.

At the Si Invernizzi site, a photovoltaic park is installed. Additionally, IGOR will inaugurate a second photovoltaic park at a new production site in 2024.

IGOR is equipped with two cogeneration plants designed for energy savings. These plants not only significantly reduce emissions into the environment but also minimize energy waste, by producing both electricity and heat.

IGOR has reduced its Scope 1 and Scope 2 CO2e emissions by increasing its consumption of energy from renewable sources.

The excess whey generated from milk processing is concentrated through a low-energy absorption osmotic system. The demineralized water obtained from this process is reused within the production cycle.

In 2020, IGOR launched the BEE-FRIENDLY project, which involved the establishment of a beehive site at the Cameri headquarters, located on the edge of the Ticino Valley. This environment is suitable for the development and pollination of bees, contributing to biodiversity protection and land conservation.

IGOR has been committed for several years to reducing greenhouse gas emissions through various energy efficiency measures. As an additional virtuous initiative, in 2023, we cancelled 16,044 carbon credits derived from the REDD+ Mai Ndombe project, which aligns with the international standards of the Paris Agreement.

In 2023, IGOR hired 41 new employees, bringing the total number of group employees to 341.

98% of the contracts for IGOR Group employees are permanent.

In 2023, we received a total of 4 awards for the quality of our products.

IGOR is strongly dedicated to supporting numerous social initiatives, actively collaborating with NGOs and sports associations. This commitment reflects the company's desire to contribute to the well-being of the community by promoting values of solidarity, inclusion, and health through the support of projects and activities that foster social development and community engagement.

IGOR enthusiastically supports women's volleyball. There are 250 girls registered in the Igor Gorgonzola Volley Novara team, 50 women's volleyball clubs participating in our SINERGY project, and 500 young athletes registered with the Consortium of Youth Societies of Novara.

Every year, IGOR receives the Charity Award from the Banco Alimentare association in recognition of its ongoing support through product donations